SWAMI SAMARTH PET INDUSTRIES

Featured Products

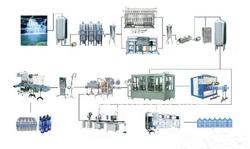

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWAMI SAMARTH PET INDUSTRIES

Automatic Pet Blow Molding Machine

Swami Samart Pet provide Hot Fill Pet Blow Molding Machine which are known for their durability, reliability and longer service life. These machines are offered as per the required specifications of our clients. These Hot Fill Pet Blow Molding Machine are used in making of beer bottles, oil bottles, chemical bottles, package drinking water, packing chemical, packing agro products. Our Hot Fill Pet Blow Molding machines have following technical advantages: These are two stage, biaxial type stretch blow moulding machine with simple and unique design It uses combination of pneumatic and hydraulic versions for a better quality output Robustness and long lasting service of component are protected by mechanical and electrical safety systems Constant quality of bottle production is based on the precision rotation of preform mandrel and stretch motions Preform carriers and blow cells are easily changeable allowing product versatility. The main function of start up operations are combined on the machine integrated LCD Control Panel Trouble Storage can be accomplished by accessing the LCD Display Screen Multiple security devices insure the safety of operators and protect the machine Some salient features of our product are: Built-in Philips automatic microprocessor High quality cylinders and valves are standard equipment of the machine Pressure adjustable valve controls fast/slow mould platen opening and closing The valves control the pressure of the compressed air, excessive air is vent out through a silencer Machine maintenance, testing and production have manual and semi auto mode Genuine parts are used to enhance machine life Specialized Heaters with directional counting for better heat transfer In built cooling system for neck cooling In built pipe line to control the temperature of mould by just attaching mould temperature controller.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.